definition of knoop hardness test|knoop hardness chart : importing Knoop hardness, a measure of the hardness of a material, calculated by measuring the indentation produced by a diamond tip that is pressed onto the surface of a sample. The test .

WEB23 de fev. de 2024 · Marseille 12. Marseille 05. Les Aygalades. Saint-Jean du Desert. Current local time in Saint-Jerome, France. Time zones CET, Central European Standard Time, Europe/Paris. Saint-Jerome UTC/GMT offset, .

{plog:ftitle_list}

web19 de fev. de 2024 · Atualmente, a escola conta com 600 alunos matriculados do 1º aos 5º anos, distribuídos em 24 salas de aula. 21/02/2024

The Knoop hardness test method is one of microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be .Learn how to use Knoop microhardness testers and testing machines to analyze the hardness of brittle and thin materials such as ceramics and coatings – with knowledge and insight from Struers, the world’s leading .

In the Knoop hardness test, an optical method, the size of indentation left by the indenter is measured. The larger the indent left by the indenter at a defined test force in the surface of a workpiece (specimen), the softer the tested material.The Knoop hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an . Among the array of hardness testing methods, the Knoop Hardness Test stands out as a valuable technique for evaluating the hardness of brittle and thin materials. In this guide, we'll delve into the principles, procedure, and .

Knoop hardness, a measure of the hardness of a material, calculated by measuring the indentation produced by a diamond tip that is pressed onto the surface of a sample. The test .A method of measuring the hardness of a material using a microscope (developed by F. Knoop in 1939), in which a pyramidal diamond point is used to make an indentation into the .The Knoop hardness (HK) results from the quotient of the test force (F in newtons N) and the projection surface (surface area) of the indent, calculated using the longer diagonal (d in .

Knoop Hardness. In subject area: Chemistry. The test involves making a Knoop hardness indentation in the surface of a flexural bar, thereby forming a crack underneath the indentation site, removing the residual stressed zone .Hardness testing assesses a material's ability to resist permanent deformation at its surface by applying pressure with a harder material. . Hardness Testing: Definition, How It Works, Types, and Benefits . Knoop Hardness Test: Similar to the Vickers test, but with a more elongated diamond-shaped indenter. It’s preferred for thin .Figure 17 shows the Knoop hardness at room temperature (load: 4.9 N) of a high-quality synthetic type IIa diamond in (001) 〈 100 〉 (the 〈 100 〉 direction on the (001) plane: henceforth, similar expressions will be employed) plotted .

Knoop hardness numbers are often cited in conjunction with specific load values. ASTM D-1474 deals with standard test methods for indentation hardness of organic coatings. In this test, Knoop hardness determinations are made at .

knoop hardness vs rockwell

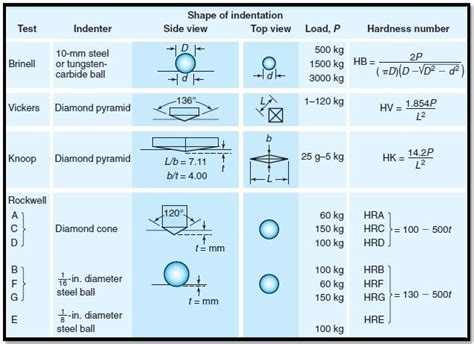

The Knoop hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work.The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation which. The Knoop Hardness Test is a micro-indentation test method specifically designed for evaluating the hardness of brittle materials, thin coatings, and small parts. Principles of the Knoop Hardness Test. The Knoop Hardness Test operates on the principle of measuring the depth of indentation produced by a pyramidal diamond indenter under a .The conventional hardness test methods, Rockwell, Brinell, Vickers and Knoop, follow a similar basic test procedure. An indenter of known s hape and material is forced into a sample under a known force. The hardness value is based on a specific measurement of the resulting indentation. The Rockwell hardness test is a one-step process where the The Knoop hardness test is conducted in the same manor, and the the same tester as the Vickers hardness test. However, only the long diagonal is measured. This, of course, saves a little time. The Knoop hardness is calculated from .

There are two main methods of microhardness testing, both offering repeatable and accurate results: Vickers hardness testing and Knoop hardness testing. Vickers hardness testing. The Vickers hardness test uses a Vickers indenter, which is shaped like a squat pyramid and is typically pressed into the surface of the material for 10 seconds. Knoop Hardness Test: This test measures the size of an indentation made on the surface of the material by a diamond pyramid under a specific load. This test is commonly used for brittle materials or thin coatings. . Understanding “Expell”: Definition, Usage, and Context 2024; Saffron: Uses, Harvesting, Medical Properties and More;

This paper describes the process used by the Consultative Committee for Mass and Related Quantities - Working Group on Hardness (CCM-WGH) of the International Committee of Weights and Measures (CIPM) to develop international definitions of the conventional Rockwell, Brinell, Vickers and Knoop hardness test methods, for use by the National Metrology .

The Brinell, Vickers, Meyer, Rockwell, Shore, IHRD, Knoop, Buchholz, and nanoindentation methods used to measure the indentation hardness of materials at different scales are compared, and main issues and misconceptions in the understanding of these methods are comprehensively reviewed and discussed. Basic equations and parameters .The test was devised in 1939 by F. Knoop and colleagues at the National Bureau of Standards in the United States. By using lower indentation pressures than the Vickers hardness test, which had been designed for measuring metals, the Knoop test allowed the hardness testing of brittle materials such as glass and ceramics.Knoop Hardness Testing: Employs a diamond penetrator to impress a sample; Shore Hardness Testing: . In-depth definition of hardness testing involves evaluating the hardness level of a material by measuring the depth or area of indentation left by an indenter of a specific shape, applied with a specific force for a specific time. .numbers shall be followed by the symbol HV for Vickers hardness, or HK for Knoop hardness, and be supplemented by a value representing the test force in kgf. Examples: 450 HV 10 = Vickers hardness number of 450 obtained with a test force of 10 kgf, 700 HV 0.1 = Vickers hardness number of 700 obtained with a test force of 100 gf (0.1 kgf), 500 .

In the Knoop hardness test, an optical method, the size of indentation left by the indenter is measured. The larger the indent left by the indenter at a defined test force in the surface of a workpiece (specimen), the softer the tested material.Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).DEFINITION OF THE VICKERS HARDNESS TEST The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. . However, the Knoop hardness test is often used when hardness . The Knoop Hardness Test measures the hardness by evaluating the measured resistance of a material to indentation, abrasion, deformation, or machining. An indentation is an asymmetric pyramidal diamond, and the indentation is .

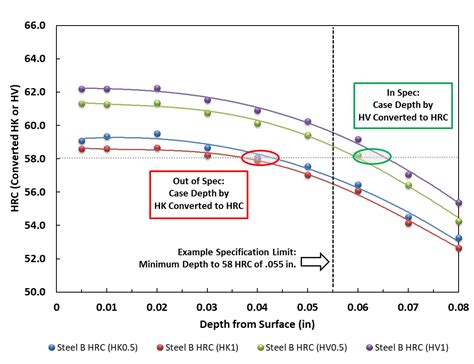

In this paper, the Vickers and Knoop hardness test methods for the determination of microhardness are discussed and a simplified method for comparison of numerical hardness number values are presented. Microhardness testing enables the .ISO 4545-4, Metallic materials — Knoop hardness test — Part 4: Table of hardness values [3] ISO 14577-1, Metallic materials — Instrumented indentation test for hardness and materials parameters — Part 1: Test method [4] ISO 18265, Metallic materials — .

5.5 Knoop Hardness Test. Knoop hardness test, or Knoop microhardness test, involves the use of a rhombic-based pyramidal diamond indenter that forms an elongated diamond shaped indentation. The diamond indenter is pressed into the test material by applying an accurately controlled force, P, in the range of 1–1000 grams. The load is maintained .Vickers Hardness The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr-amid. It is commonly used for measuring the hardness of thin coatings or materials with a small indentation requirement. Knoop belongs to the optical methods. Knoop HardnessKnoop hardness test synonyms, Knoop hardness test pronunciation, Knoop hardness test translation, English dictionary definition of Knoop hardness test. n. 1. A procedure for critical evaluation; a means of determining the presence, quality, or truth of something; a trial: a test of one's eyesight;.The hardness numbers shall be followed by the symbol HV for Vickers hardness, or HK for Knoop hardness, and be supplemented by a value representing the test force in kgf. Examples: 450 HV 10 = Vickers hardness number of 450 obtained with a test force of 10 kgf, 700 HV 0.1 = Vickers hardness number of 700 obtained with a test force of 100 gf (0. .

This paper describes the process used by the Consultative Committee for Mass and Related Quantities - Working Group on Hardness (CCM-WGH) of the International Committee of Weights and Measures (CIPM) to develop international definitions of the conventional Rockwell, Brinell, Vickers and Knoop hardness test methods, for use by the National Metrology Institutes (NMI) . 2. Knoop microhardness testing For microhardness testing according to Knoop, the indenter has the shape of an extended pyramid. It has a length to width ratio of 7 to 1 and angles of 172 degrees for the long edge and 130 degrees for the short edge. This rectangular shape makes the Knoop method a better fit for small, long samples.

The Knoop test utilized a shallower, elongated format of the diamond pyramid and was designed for use under lower test forces than the Vickers hardness test, allowing for more accurate testing of brittle or thin materials. . Hardness testing technology remained fairly consistent throughout the mid to latter 1900’s, most systems typically .

knoop hardness vs glass types

WEBAPRENDA A VIVER DA ITERNET!!!https://bit.ly/3pKNIgGconfere láhttps://youtu.be/Dhf0FuUjOTc

definition of knoop hardness test|knoop hardness chart